BK MIKRO

Reliable Tool Monitoring

Tool breakage? Clamping error? Misfeed? BK Mikro stands for the absolutely safe monitoring of work processes in industrial production processes. This monitoring is achieved by means of intelligent sensor system solutions based on sound technological knowledge and industry-specific application experience. Precision and quality are the basis of a maximum degree of constant safety - Made in Germany.

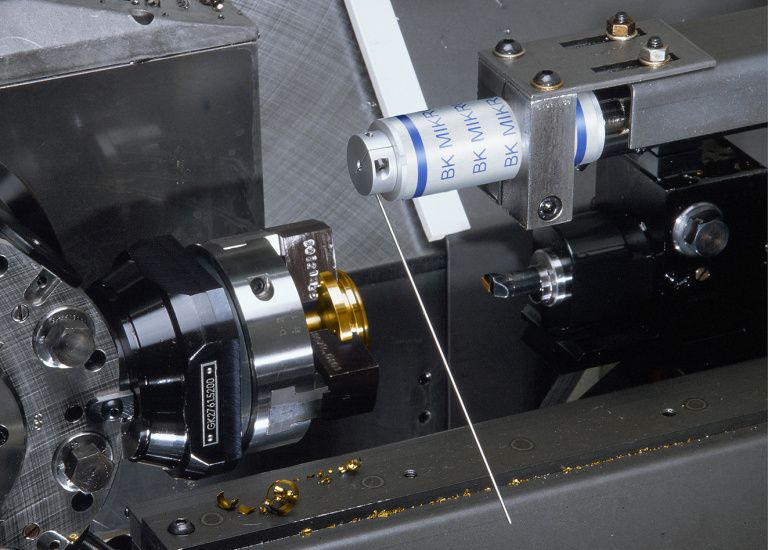

The system consists of a control unit for top-hat rail assembly and a tactile sensor resp. probe precisely attuned to the respective process situation. Presence, correct position and freedom from breakage are identified and slightest deviations from the defined normal condition are quickly detected. If a fault occurs, an instantaneous machine stop can be initiated to prevent further damages or defective products.

More than 40 years of BK Mikro

Micro Process Monitoring through Precise Tool Monitoring

A small product, but a giant leap in terms of process safety. Starting in 1980 with the first electrical system for drill control, the sensor systems of BK Mikro are now globally established in machine building resp. the machining industry.

Meanwhile, it is no longer “just” about tool resp. tool breakage monitoring. The preventive application of BK Mikro is part of the condition monitoring to keep an eye on all major technical parameters of a machine and supports predictive maintenance. Today more than ever, production reliability resp. traceability are decisive factors for safe and efficient production processes.

Wherever highest precision is required, BK Mikro fulfils its task with diligence: Monitoring tools, checking objects, detecting positions, measuring hidden geometries, checking contours/profiles.

1980: First presentation of BK Mikro

Leukhardt Systems presents BK Mikro, a solution for tool monitoring in machines. This first product is at the same time the first electrically driven system.

1990: BK Mikro goes international

Now BK Mikro is drawn towards the USA. The first trader in the USA distributes BK Mikro products such as sensors, control units and accessories while also providing support.

1994: BK Mikro5 is patented

BK Mikro5 is the first system with right-left scanning which allows the monitoring of two exactly detected scanning positions (clockwise and counter-clockwise rotation of the wand and automatic detection of the rest position).

2000: BK Mikro8 allows to monitor several tools

With an integrated PROFIBUS resp. digital E/A BK Mikro8 offers the precondition for the monitoring of several tools right in the machine tool with just one system.

2006: Own distribution network for BK Mikro launched

With the establishment of its own distribution network BK Mikro now lays the cornerstone for global expansion.

2007: Modularity with BK Mikro

A new era begins: From now on, the different control units can be combined with different sensors.

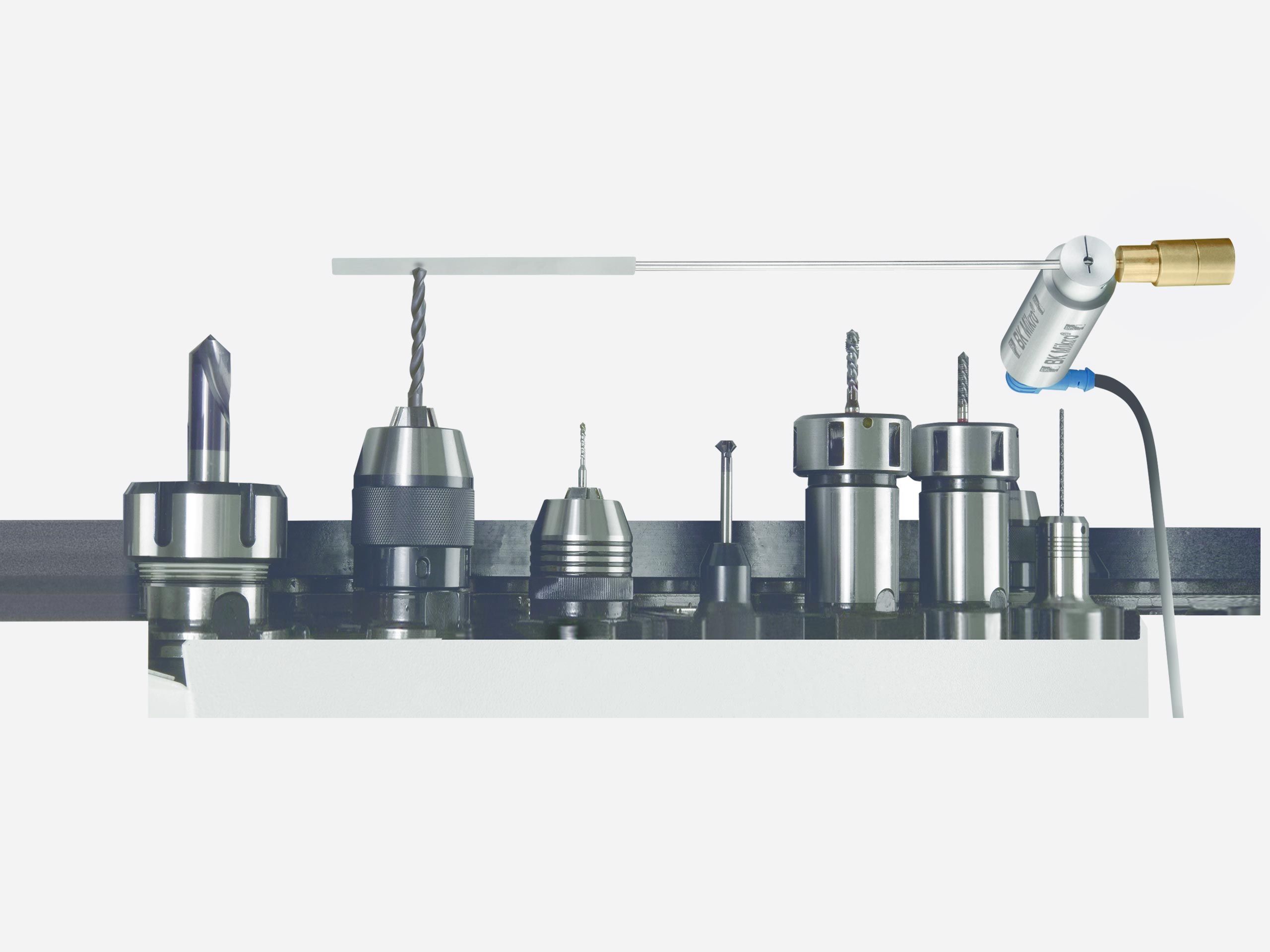

2014: New sensors now test from 0.1 mm

With the new sensors TK7 and TK 96 it is now possible to monitor particularly fine rotating tools. The new sensors scan tools from 0.1 mm.

2020: 40 years & 150,000 sensor systems

Time to celebrate: BK Mikro has been successful with a global sales and service network for 40 years. As of today, 150,000 sensor systems are in use.

The BK Mikro Products

The system achieves its high degree of flexibility and adaptability by its components.

Flexible customization

The accessories

BK Mikro offers an extensive range of accessories and spare parts to optimally fulfil the requirements of monitoring tasks. This means that the system can be customised for a wide range of tasks and the most difficult operating environments.

All safely under control

Interested?

Would you like to be informed about product and other news relating to BK Mikro as well as trade fair dates and events? Then register now.