Embedded Components

We develop and produce computer hardware, electronic assemblies and components for our own standard products as well as for customised solutions for use in industry, medical technology, mechanical engineering, the food and hygiene sectors and more. Here we show a selection of our products and current projects in the areas of Single Board Computers, touch display units control elements and extension cards.

Web Panel

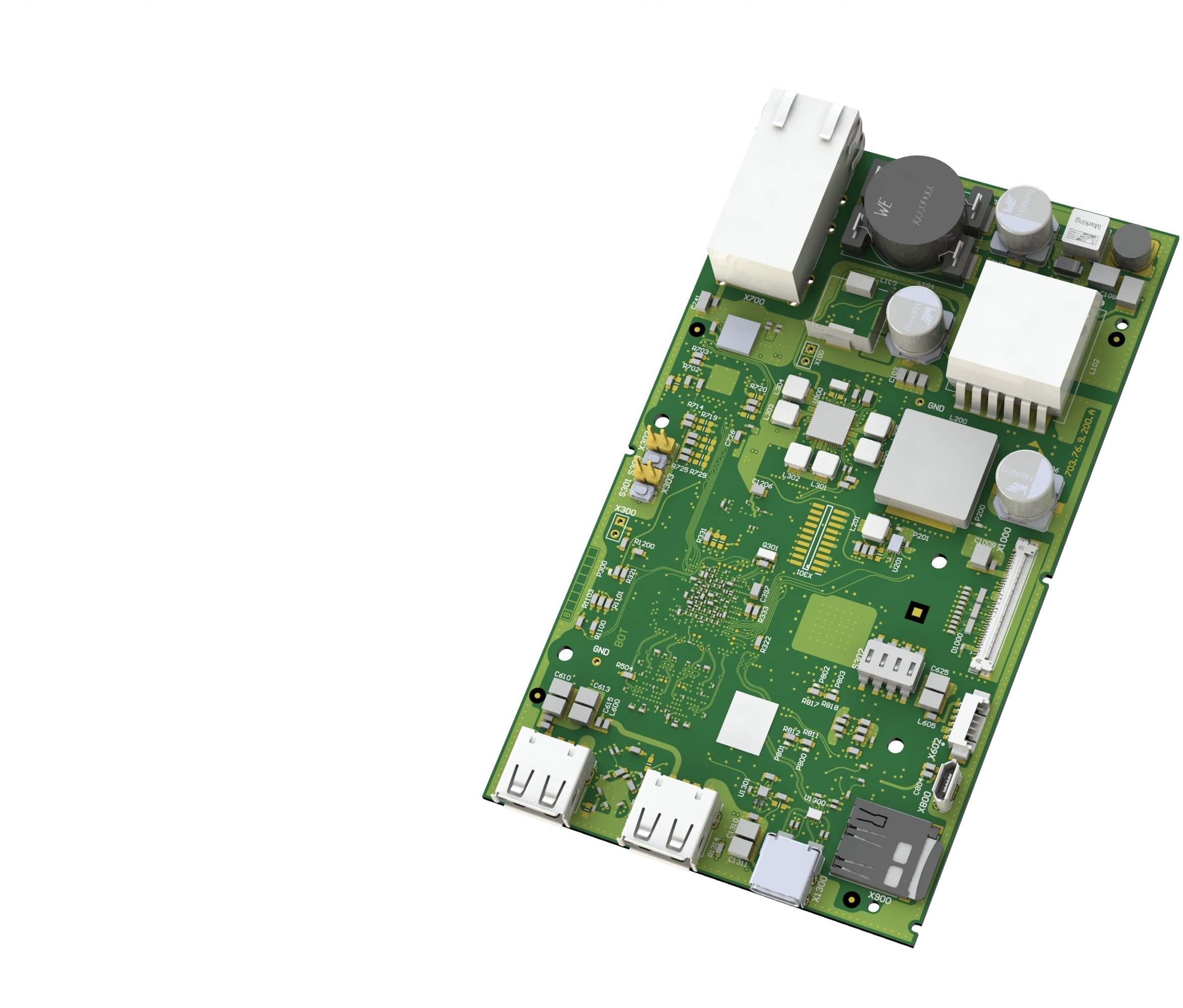

Single Board Computer

- SBC in-house development for integration in Prime Cube Web Panel

- Arm64 base with NXP i.MX 8M plus CPU, PoE

- Display resolution up to 1366 x 768 px

- Own Board Support Package, Embedded Linux Support

- Functional enhancements are offered project-specifically

The product is the result of an interdisciplinary development project comprising system development, platform development and software concept. The industrial single board computer with our own form factor has a production-optimized design and is manufactured and tested fully automatically in our own electronics production facility.

Hygienic Applications

Multitouch Display unit with protective glass and individual Touch Configuration

- Hygiene-optimized assembly precisely tailored to the customer's housing concept

- Slim design by attaching the TFT display to the front glass using air bonding

- PCT touch sensor parameterized for special requirements in the medical environment (EMC stability, glove operation)

- Attractive appearance by adapting the glass dimensions, edges and radii as well as printing and touch position

Engineering took place together with the customer, starting with the system concept and iterative testing of the display unit. Thanks to immediately available sample glasses and displays including control, an optimal display solution for the application in the field of ophthalmology could be developed in a short time.

Automation

Compact display unit

- Compact 2" display for displaying process parameters in safety-critical screwdriving applications Application

- Full-color TFT display with optimized LED backlight for increased ambient temperatures

- Long-term availability based on an STM32F4 ARM Cortex.M4 microcontroller

The monochrome LCD previously used by the customer showed massive deviations in the visual impression. After a detailed analysis including thermal simulation, the existing system was replaced by a customized hardware and software development. The complete emulation of the previous chipset enables seamless continued operation of the application (plug & play).

Connectivity

Display card for touch panel monitor

- In-house development for use in Prime Panel Touch

- among othersmax. resolution 1920 x 1200 px

- DP, DVI, 24 V input

- Standard menu, support for integration and additional components (power supply units, mains filters, cable systems), parameterisation

Setting down touch monitors

With Prime Extend, touch monitors can be placed over a longer distance of up to 100 metres. The image and operating data are transmitted securely and without delay.

- Display port and USB 2.0 transmission

- Latency-free transfer of USB data and full HD video

- Cat 6a or Cat 7 standard Ethernet cable

- Flexible power supply in 5 V, 12 V and 24 V

- Temperature range - 20 °C to +50 °C

- Plug & play: simple integration into existing infrastructure

- More about the product

TX board

- Compact layout fits into standard top-hat rail housings

- Industrial Display Port interface instead of HDMI

- 24V input

RX board

- Direct internal connection via LVDS to an existing display

- Configuration data is created (timing, resolution)

- Slim system, no additional card required

Control elements

MCI (Machine Control Interface) stands for a modular concept for the realisation of operating elements on an HMI or in larger panels for machine operation.

The basic system is used to connect the individual components such as the keypad or a feedback override and can be parameterised individually. In the open system, changing requirements can be easily implemented with additional components. It is independent of the PLC.

MCI Button Module

Customer-specific controllable button module, RGB lighting, customised symbols

MCI Piggyback

Communication module with multiprotocol chip, for fieldbus connection of MC2 components

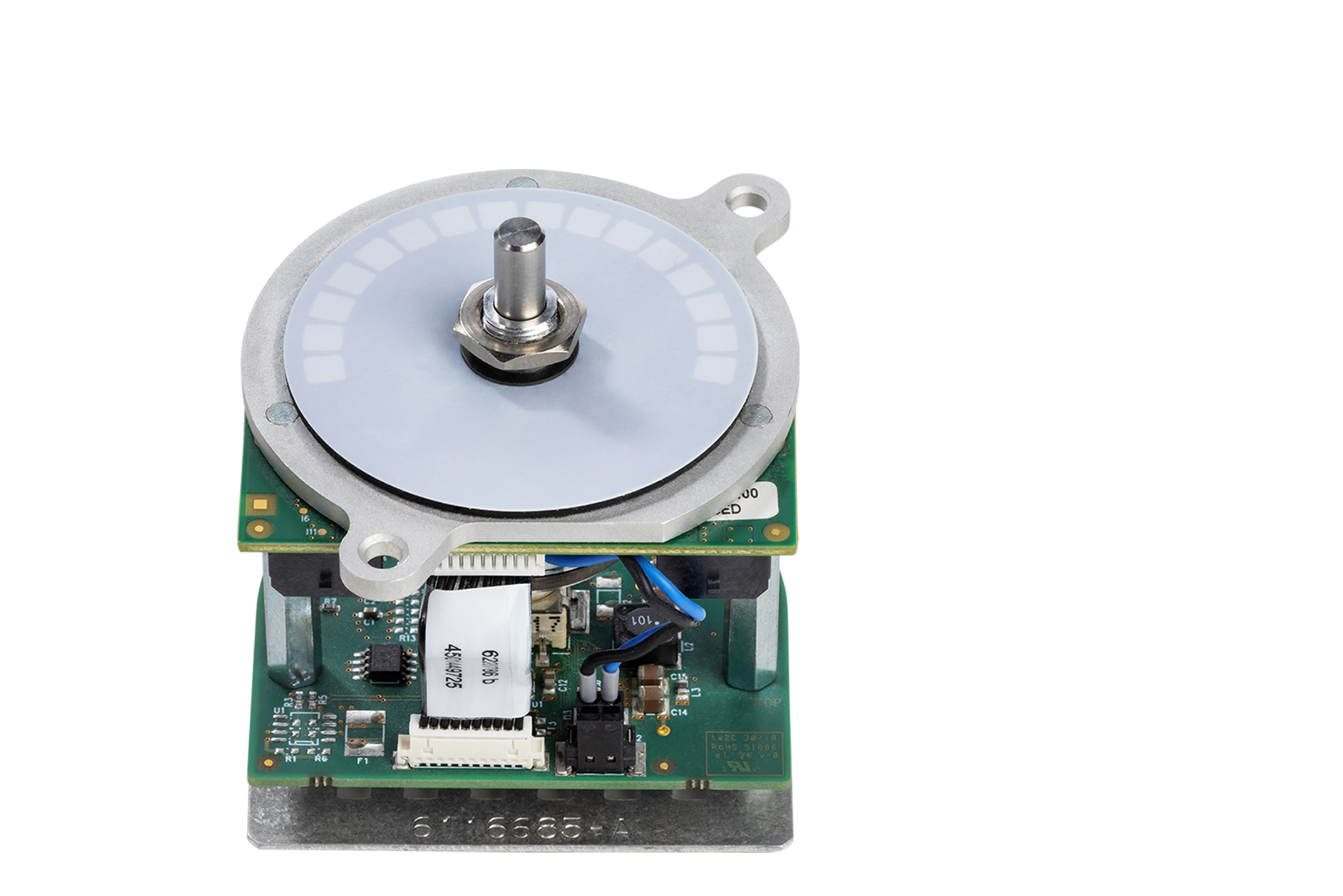

Feedback Override

Customized controllable override module; RGB lighting, controllable limiting

Contact us

Do you have an initial idea or a specific requirement? Our sales engineers and specialists will be happy to support you.

Customised development

We support and advise our customers throughout the entire development process, from the initial idea to series production, and derive new products from the projects. You benefit from our more than 50 years of experience and expertise in all areas of development

- System development

- Embedded and system software

- Hardware

- Construction and mechanics

- Verification and validation

Technology partners

We work with a global network of suppliers and partners and are a member of the Intel Partner Alliance in the field of x86 computer technology, for example.

In the field of Arm architecture, we prefer to work with the manufacturers ST Microelectronics and NXP.

Development and production in Germany

Our hardware and software development takes place at our main site in Neuhausen ob Eck and in our Software Lab in Deggendorf.

We also cover all key production stages in Neuhausen ob Eck. In 2021, we strengthened our vertical integration with an SMD line, on which the electronic assemblies developed in-house are manufactured.

We therefore realise all important development steps from the initial idea to series delivery in Germany.